The 451 is a potential hinge product which is fitted to a door or forms part of a hinge assembly with a half round hinge door edge. This half round heel of the door rolls along the flat door frame reveal as the door rotates to open and close either in or out. The door will rotate into a space ninety degrees and out of the space ninety degrees if it rolls along a traditional flat door frame reveal (without a frame stop) at the heel of the door. If the door frame is a similar half round section, like the door, and is of similar thickness to the door, the door can then open into the space one hundred and eighty degrees and out of the space one hundred and eighty degrees. If the door opens only one way (say in) a quadrant on the hinge frame will allow a door to open in one hundred and eighty degrees in only one direction. The hinge side of the frame can be of ferrous material or part ferrous material to ensure standard magnets (annulus shaped) will to be attracted to the ferrous frame or part ferrous frame. The term part frame also includes patches or plates of ferrous material to attract the door or frame mounted magnets. The arrangement could work in a similar fashion if the magnetic material was on the the door or frame or if mating magnets are used on both parts. The magnets can be mounted to the top and bottom of the door however this description does not refer to a definitive type or number. The type of magnet does not preclude strips or part strips of flexible magnetic material. The vertical component of the mass of the door can be carried by a two part bearing system comprising a rubbing or bearing block secured to the the floor and a self lubricating disc in the bottom of the hinge edge of the door. As the door opens or closes the disk may roll along the hinge frame while part sliding on the floor bearing block. A friction or other restraint component is required to keep the vertical axis vertical and prevent the heel of the door sliding off the bearing block or the top of the door moving away from the vertical axis on which it rotates. The friction restraint component could be full height, or be top and bottom of the door or form patches along the hinge edge of the door. The friction or other restraint may be a high friction fabric, tapes in tension, elastic material or a hook and loop material. Alternative restraint devices or materials are not restricted to fabric but also include toothed gear components and or toothed engineered ribbons similar to fabric timing belts. This restraint device could also include plastic type blocks ( with two axis rotation) or other bearing material that rotate at the centre line of the door and frame. This also applies to a restraint at the top of the door where the gravity load carrying bearing assembly is not required. If a plastic block material is used at intervals along the hinge line then the bearing block assembly on the floor could be eliminated. The whole arrangement including ferrous jamb part, bearing assembly or intermediate bearing blocks and magnets could all be configured in a hinge gearing system in a full height metal extrusion to house the magnets or magnetic material) not dissimilar to some existing products like a geared full height piano hinges. The whole arrangement could also be based on half round geometry or even quarter round geometry for doors that only open one way up to ninety degrees. The hinge edge of the door is held in place by the magnetic attraction of the parts and the friction or other restraint material keeps the door panel vertical and true. I believe that the frame can be installed with the traditional methods however to install the special magnetic door panel part is facilitated with ease and reduced skilled labour with little time spent preparing the door and frame for hinge hardware. The arrangement as described above can open in and out, open up to one hundred and eighty degrees, can prevent tiny digits being crushed, can be used for rescue of frail aged folk from tiny toilet rooms. This document is publication of a new product to ensure the work of John Howard Styles is not claimed by others as theirs. Notes - John Howard Styles -Canberra 13.8.2020

Monday, 24 September 2018

INTERESTING FAST-FIX HARDWARE SUITABLE FOR AGED FOLK RESCUE EQUIPMENT

Thursday, 30 August 2018

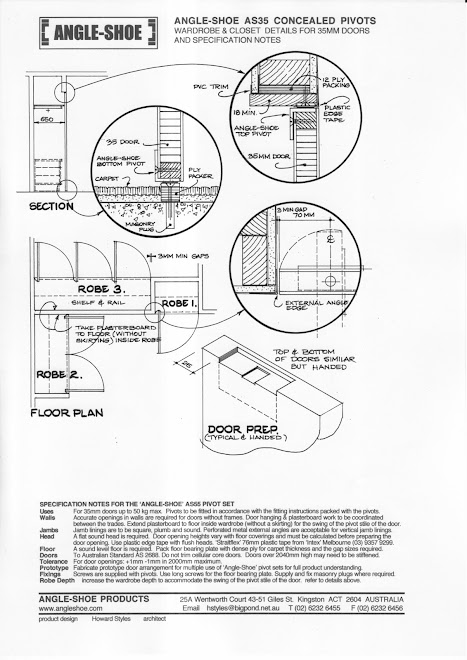

The Bold Claims (Faster, Cheaper & Crispier)

Based on a 35mm (1 3/8") pre-prepared & pre-finished door;

For bedroom, bathroom, closet and similar internal doors

1. No traditional door frame

2. No door frame stop bead

3. No architraves (no mitered timber trim moldings to perimeter of frame)

4. Reduces the need for nib studs and double studs

5. Eliminates site painting of doors & frames (roller work only to reveals)

6. Integral concealed magnetic catch eliminates the need for a latch bolt

7. Lever handles not required

8. Labour on the above items greatly reduced

9. Limited trade skills required to hang doors

10. Simple tools required (drill & screwdriver)

11. Simplified floor finishes (minimal scribing around moldings)

12. Non-handed hardware (flip & rotate door to change hand)

13. Simple concept to sell to clients, specifiers, developers & builders

Note - There are add-on costs (plumb plasterboard work & set plaster trim etc.)

This product has been designed by;

Door & Hardware Specialist Architect - Howard Styles

Canberra Australia

61 2 6232 6455

Tuesday, 26 June 2018

Monday, 18 May 2015

Concealed Pivot Hinges for ACP (Aluminium Composite Panels)

ACP (Aluminium Composite Panels) like all crisp facade systems need concealed pivot details for access panels, hatches and service doors. They are required for; electrical, hydraulic, data and other service closets and for access doors to other services. Angle-Shoe pivots have the hardware to do the job. They can be used for very small access panels into the centre of a sheet with only a 3mm (1/8") gap visible. They can also be used for access doors to 50kg (100 pounds).

For further information contact the designer Howard Styles. E hstyles@bigpond.net.au

The image below is the AS35(ex) pivot which has a weather seal and a brass rivet.

For further information contact the designer Howard Styles. E hstyles@bigpond.net.au

The image below is the AS35(ex) pivot which has a weather seal and a brass rivet.

Wednesday, 15 October 2014

Monday, 13 October 2014

Low Cost 'Angle-Shoe' Pivot

Angle-Shoe Pivots are testing a low cost pivot for affordable housing. Traditional pivots cost a lot to purchase and install. This pivot will be considerably cheaper than the original economical Angle-Shoe AS35.

The new model is for hollow core doors 2040 x 870 x 35 (6'8" x 2'10" x 1 3/8") The test door is 35Kg (70 pounds) to allow for some variation to the panel type.

The big savings for flush pivot doors in gypsum plasterboard walls is in the painting cost. To prime, undercoat and paint a door with a normal architrave or similar timber trim in Australia costs about AUD$150.00 or about five times the purchase cost of the door panel. For these pivot doors the painting can be done with just a paint roller without 'cutting-in' brushwork. For details of the new 'PAS35' please email Howard Styles - hstyles@bigpond.net.au

The new model is for hollow core doors 2040 x 870 x 35 (6'8" x 2'10" x 1 3/8") The test door is 35Kg (70 pounds) to allow for some variation to the panel type.

The big savings for flush pivot doors in gypsum plasterboard walls is in the painting cost. To prime, undercoat and paint a door with a normal architrave or similar timber trim in Australia costs about AUD$150.00 or about five times the purchase cost of the door panel. For these pivot doors the painting can be done with just a paint roller without 'cutting-in' brushwork. For details of the new 'PAS35' please email Howard Styles - hstyles@bigpond.net.au

Wednesday, 7 May 2014

USA 'ANGLE-SHOE' MANUFACTURERS

'ANGLE-SHOE' MANUFACTURERS IN THE USA'

This can now be considered 'Trumpian' Fake News

'ANGLE-SHOE' pivots will NEVER be made in the USA. A manufacturer has show a keen interest in the ever growing range of products and negotiations are under way to service that part of the global market. For architectural hardware distributors please email Howard Styles at hstyles@bigpond.net.au - for contact details.

THE PFS35 LOW COST PIVOT SETS

Angle-Shoe' pivots were officially launched at DesignBuild Melbourne in 2004.

Thousands of pivots sets have now been sold to a bunch of very happy customers.

The pivots go to places like Curaçao, Suriname, Holland, and even New Zealand.

Some also go to the UK and USA.

Howard Styles the designer and maker of Angle-Shoes makes the pivots in Canberra.

Unlike Washington DC, Canberra is not only the nations capitol but is also:

'The Epicentre of pivot making in Australia'.

The pivots are constantly morphing into new products to facilitate economical details.

This can now be considered 'Trumpian' Fake News

'ANGLE-SHOE' pivots will NEVER be made in the USA. A manufacturer has show a keen interest in the ever growing range of products and negotiations are under way to service that part of the global market. For architectural hardware distributors please email Howard Styles at hstyles@bigpond.net.au - for contact details.

THE PFS35 LOW COST PIVOT SETS

Angle-Shoe' pivots were officially launched at DesignBuild Melbourne in 2004.

Thousands of pivots sets have now been sold to a bunch of very happy customers.

The pivots go to places like Curaçao, Suriname, Holland, and even New Zealand.

Some also go to the UK and USA.

Howard Styles the designer and maker of Angle-Shoes makes the pivots in Canberra.

Unlike Washington DC, Canberra is not only the nations capitol but is also:

'The Epicentre of pivot making in Australia'.

The pivots are constantly morphing into new products to facilitate economical details.

Subscribe to:

Comments (Atom)

.jpg)